CORRUGATED POLYCARBONATE SHEETS INSTALLATION

Subsurface preparation of corrugated polycarbonate sheets

Frame dimensions for installing corrugated polycarbonate sheets depend on the imposed load and sheet thickness. See the polycarbonate sheet load-bearing capacity data table to calculate appropriate dimensions.

Cutting corrugated sheets

corrugated sheets can be easily cut using standard saws. Note that the sheets should be prevented from vibration, and the cutting path must be tightly fixed.

Drilling corrugated sheets: the diameter of the hole drilled into the polycarbonate sheets must be 3 mm larger than the screw. The holes should have a minimum edge clearance of 40 mm. Rubber gaskets must be used for sealing the drilled holes.

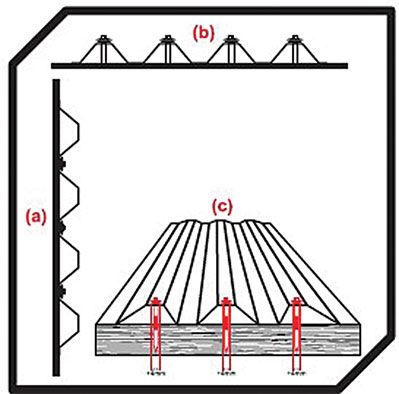

Drilling location: when using the corrugated sheets for roofs, the drilling locations must be at the crest and when using the sheets for walls (vertical structures) at the trough.

Side-by-side installation of corrugated sheets

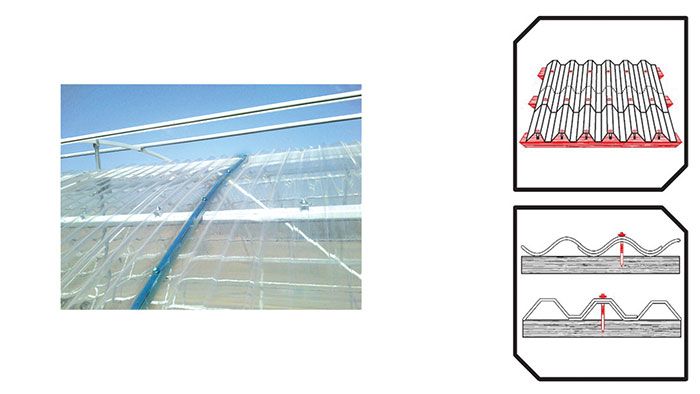

Longitudinal overlap: the sheets must be laid with a minimum 30 cm overlap for roofing applications. A 15 cm overlap is sufficient in walls. Longitudinal overlaps must be fixed by screws and flashing. Screws should not be fixed on the sheet directly. Therefore, flashing and double-sided rubber adhesive tapes must be used for pressure distribution. Furthermore, according to the physical structure of the sheet, foams with the same pitch as the sheet are to be placed under the screw-fixtures. The sheet should be first attached to the purlin by a special adhesive according to the pitch.

Transverse overlap: in this case, overlapping should be opposite to the general direction of the wind. Overlapping for the sinusoidal and V76 sheets is at least twice the pitch, and for the trapezoidal sheets is one pitch. In the case of the single-pitch overlap of sinusoidal and V76 sheets, the overlapping site should be tightly fixed by a belt under the sheet, a fish-bellied over the sheet, and a rubber tape between them.

Side-by-side installation of polycarbonate and galvanized sheets

Longitudinal overlap: longitudinal overlapping of polycarbonate sheets next to galvanized sheets is the same as that of two polycarbonate sheets with only one difference. In this configuration, the polycarbonate sheet is placed partially under the galvanized sheet. Flashing tapes should be used where the polycarbonate sheet is placed on the galvanized sheet. However, there is no need for the flashing tape in parts where the polycarbonate sheet is placed under the galvanized sheet, and only foam and double-sided rubber adhesive tapes suffice for this purpose.

Transverse overlap: this configuration is similar to the previous one, but the transverse overlap of corrugated sheets must oppose the wind direction. Whether flashing tapes are to be used depends on the longitudinal overlap of the polycarbonate sheet and its adjacent galvanized sheet.

Side-by-side installation of polycarbonate sheets and sandwich panels

Longitudinal overlap: in this case, the longitudinal overlap is at least 30 cm, and flashing and double-sided rubber adhesive tape are required at every pitch. For better sealing, it is recommended to use double-sided rubber adhesive tape between the polycarbonate sheet and sandwich panel.

Transverse overlap: flashing tape should be used on both sides of the sheet in this type of overlapping.

Due to different thicknesses of sandwich panel and corrugated sheets, a profile with the identical sheet thickness should be placed under the purlin, and then rubber foams must be attached. Instead, a piece of the sandwich panel with the same pitch (step) as the sheet can be cut and placed under the sheet. One-piece flashing should be used at every pitch.

Cold bending

these sheets can be bent only lengthwise, and not across the width. The minimum bending radius of the sheets must be also be taken into account. The minimum bending radii of trapezoidal and sinusoidal sheets are 4800 mm and 4000 mm, respectively.

Internal impact strength: to install polycarbonate sheets in places exposed to impact from beneath, such as in sports halls, 8-10 mm triangular triple-walled sheets are recommended to be laid under the sheet to protect it against impact.

Sanat Plast is the largest producer of polycarbonate sheets in Iran.

Tel: +982174616

+982122658190-2

Factory: +9807733450301

All rights reserved to Sanat Plast Pars Lian Company.

Web Design