Key concepts and tools needed

Cutting and drilling tools

Saw: polycarbonate sheets can be cut using hand, circular, band, or other saws. However, fine saws with a small dent spacing (4-5 dents per cam) should be used at high speeds. The direction of dents in circular saws should be the same as the rotation direction.

Drill: standard drills used for metals are also suitable for drilling polycarbonate sheets. Make sure the drill bits are sharp.

Sealing equipment

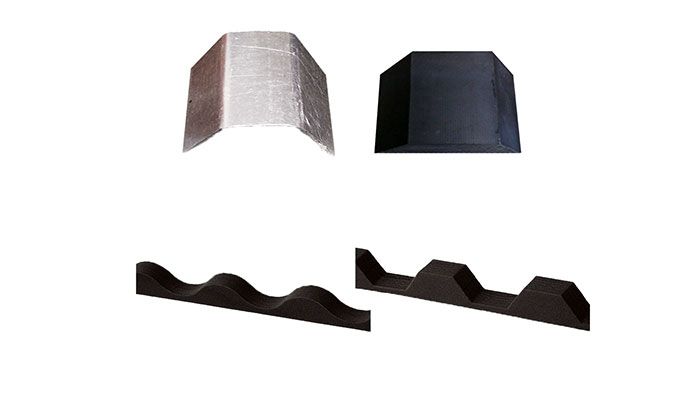

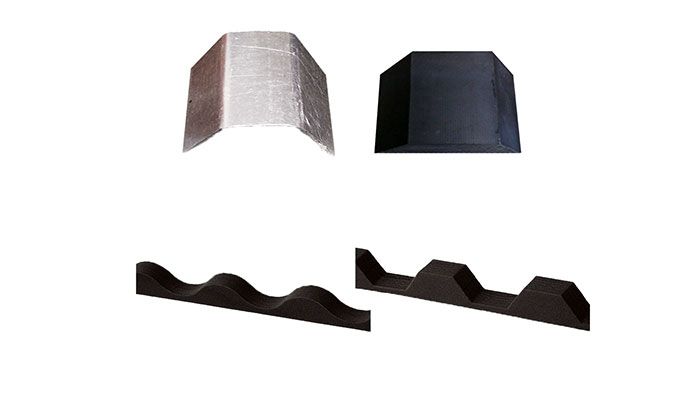

Rubber gaskets and tapes: these gaskets must be made of EPDM or polyurethane. Rubber tapes made of PVC should not be used with polycarbonate.

Sealing tapes: Sealing tapes may be made of aluminum, spunbond, and EPDM. Depending on the application, impermeable and permeable (perforated) types are used for installation.

Sealing foam (rubber foam)

EVA and XLPE sealing foams are used for polycarbonate products. Note that PVC foams or PVC-filled foams should not be used with polycarbonate products.

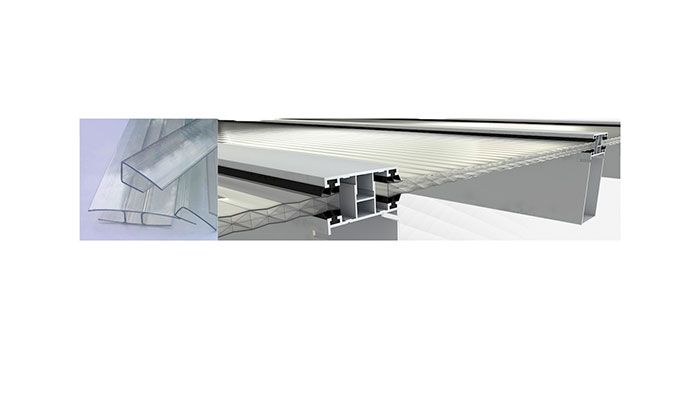

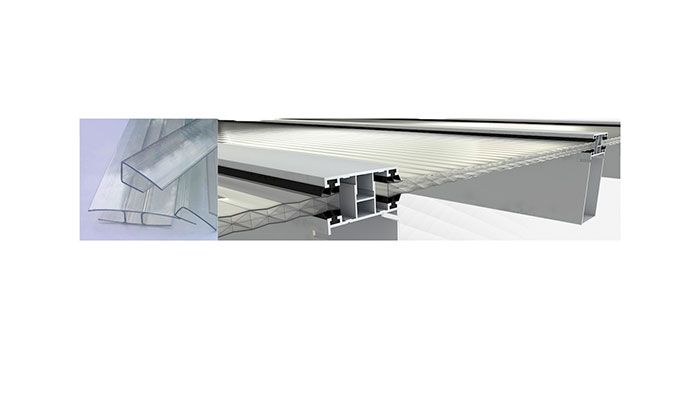

Profiles and flashing tape

The best method for connecting polycarbonate sheets is to use profiles made of aluminum or polycarbonate. It is essential to use rubber tapes while using aluminum profiles for sealing to prevent damage to sheets. Various types of profiles are discussed below based on their applications.

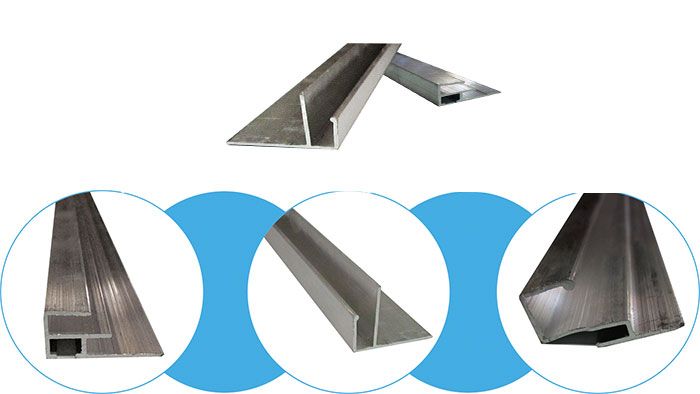

H aluminum profile

This type of profile is used for edge-to-edge sheet joints and is divided into one-piece and two-piece H profiles.

One-piece H profile

the height of one-piece profiles is selected depending on the sheet thickness.

Two-piece H profile

this type of profile has a higher strength than one-piece ones leading to more effective sealing.

F profiles

F profiles are used for connecting the end edge of sheets.

U profile

U profile is used for closing the end part of the sheet.

The fish-bellied profile

The fish-bellied profile is an aluminum tape that is used to retrofit connections or pressure distribution beneath the screw in corrugated sheets.

Flashing

when corrugated sheets are overlapping galvanized sheets or sandwich panels, the overlapping site should be tightened by a metal sheet with the same pitch (step). It should be noted that a rubber tape should be applied between flashing tapes.

Anti-UV layer

all polycarbonate sheets are coated with an anti-UV layer. This layer protects polycarbonate products against sunlight and UV irradiation. Note that the side coated with the anti-UV layer should face the sun.

Sheet protective coating: both sides of polycarbonate sheets are coated with polyethylene protective layers. The side with the anti-UV layer is marked by a labeled coating. Note that at least a small part of the labeled coating should be maintained on the sheet after installation to be inspected by an expert. However, it should not take long as sunlight joins the coating with the sheet.

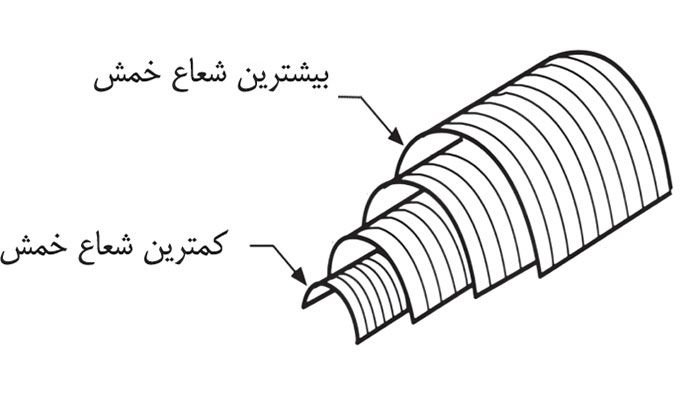

Cold bending

bending polycarbonate sheets without heating is referred to as cold bending. In this operation, the allowable bending radius should be taken into account.

Minimum bending radius

The bending radius is the radius of a circle tangent to the curve. The minimum bending radius is the smallest radius at which a sheet can maintain its structure. A smaller bending radius means that the sheet can bend further.

Longitudinal and transverse overlap

Longitudinal overlapping means placing two sheets on each other so that their lengths are in the same direction.

Transverse overlapping means the placement of corrugated sheet steps on each other.

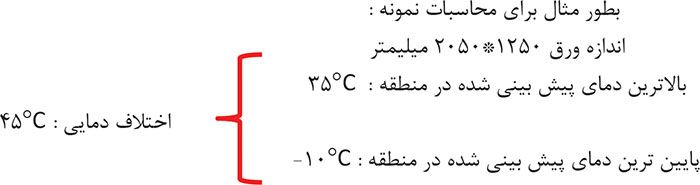

The coefficient of linear thermal

The coefficient of linear thermal

length due to a temperature change of 1 ̊C. The thermal expansion coefficient of polycarbonate is 0.068. Note that enough spacing should be considered for the expansion of sheets due to temperature variations.

Horizontal beams (purlins)

Horizontal beams (purlins) are placed in the roof of structures on the main beams (truss).

Framing: proper subsurface preparation should be in the form of 8×4 or 4×4 metal profiles or T, Z, or IPE shields. Moreover, timbers with a maximum width of 6 cm and a maximum height of 8 cm can also be used.

Load per square meter

Load per square meter equals the force exerted on a square meter. Note that this load (resulting from rain and snow) is considered to be distributed over the sheet. For example, if snow density is 100 kg/m3, 0.5 m2 snow on a roof exerts a load of 50 kg/m2. However, a person weighing 60 kg places a load of over 500 kg/m2 on the sheet. Thus, one should avoid walking on the sheets.

Neutral detergents are those with low concentrations of acidic and basic ingredients, inducing no chemical reaction with the surface of sheets.

Sanat Plast is the largest producer of polycarbonate sheets in Iran.

Tel: +982174616

+982122658190-2

Factory: +9807733450301

All rights reserved to Sanat Plast Pars Lian Company.

Web Design